From the ground up it was important to me to make sure that the models that I make are easy to print, whether that is on an FDM or a Resin 3D printer. Having worked with and owned both types, this allows me to prototype and adjust the models to ensure that the best print results can be had with the minimum of fuss.

FDM vs Resin, what’s best?

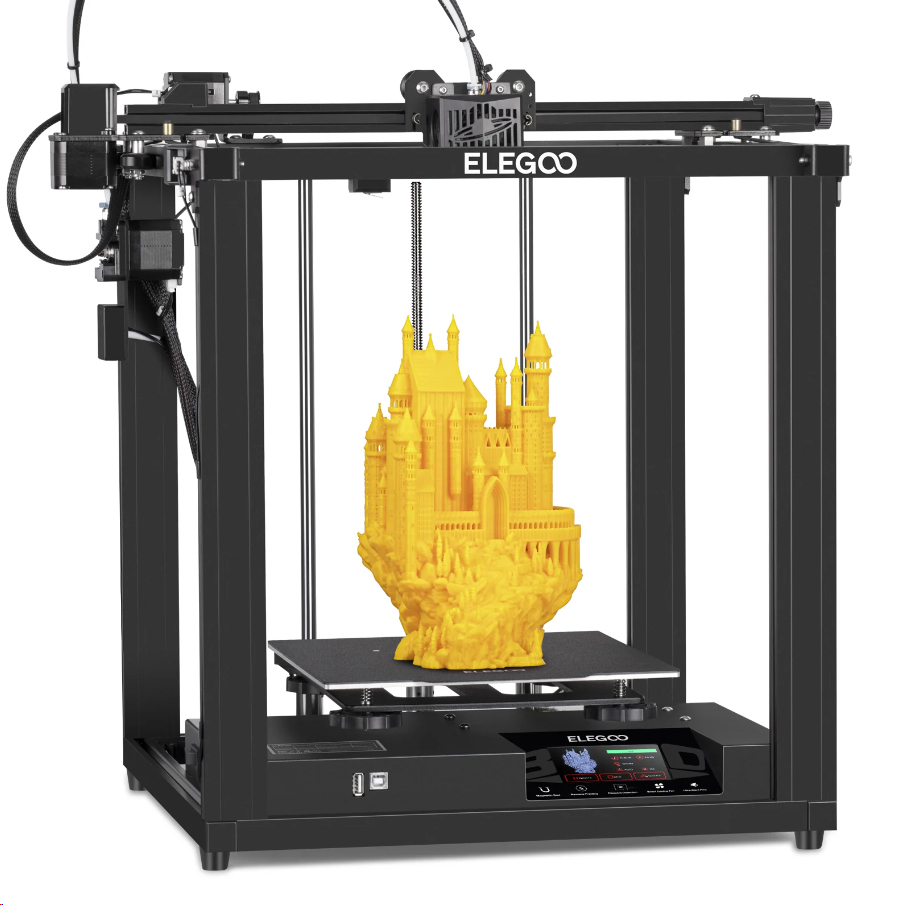

Both printing methods have their advantages and disadvantages. FDM can (at the moment) offer vastly larger print volumes than a similarly priced Resin 3D printer, but this size advantage comes with a distinct impact on print quality. FDM prints have very visible layer lines, even at the highest resolution and therefore require a considerable amount of post-processing to get a smooth finish. This can be fine in some structural areas if the layer lines are not going to be seen, but for detail areas the processing required can be a nightmare.

Resin prints, on the other hand, have a far finer resolution, albiet at a smaller overall print size. This results in less of the sand, prime, sand again post-processing, although it does have it’s own processes that have to be followed to get the best results, such as cleaning with Isopropyl Alcohol and post-curing with a UV light bath.

Another advantage that FDM has over Resin is it’s durability. Resin has a tendency to be quite brittle and, as it is a UV-cured process, exposure to sunlight can sometimes cause issues down the line. FDM on the other hand tends to be very strong, and is available in a number of high strength materials, such as nylon and carbon fibre infused filament.

For some models it may be better to print with a combination of the two – resin for the smaller. detailed parts that would be very hard for FDM to reproduce, and FDM for the larger parts that would be too expensive / time consuming to print in resin. It all comes down to how much finishing you want to have to do to the prints.